SERVICES AND PRODUCTION DEPARTMENTS

Sheet metal products

We are a leader in cold metal molding and deep drawing, with a pressing area that ensures reliability and product quality.

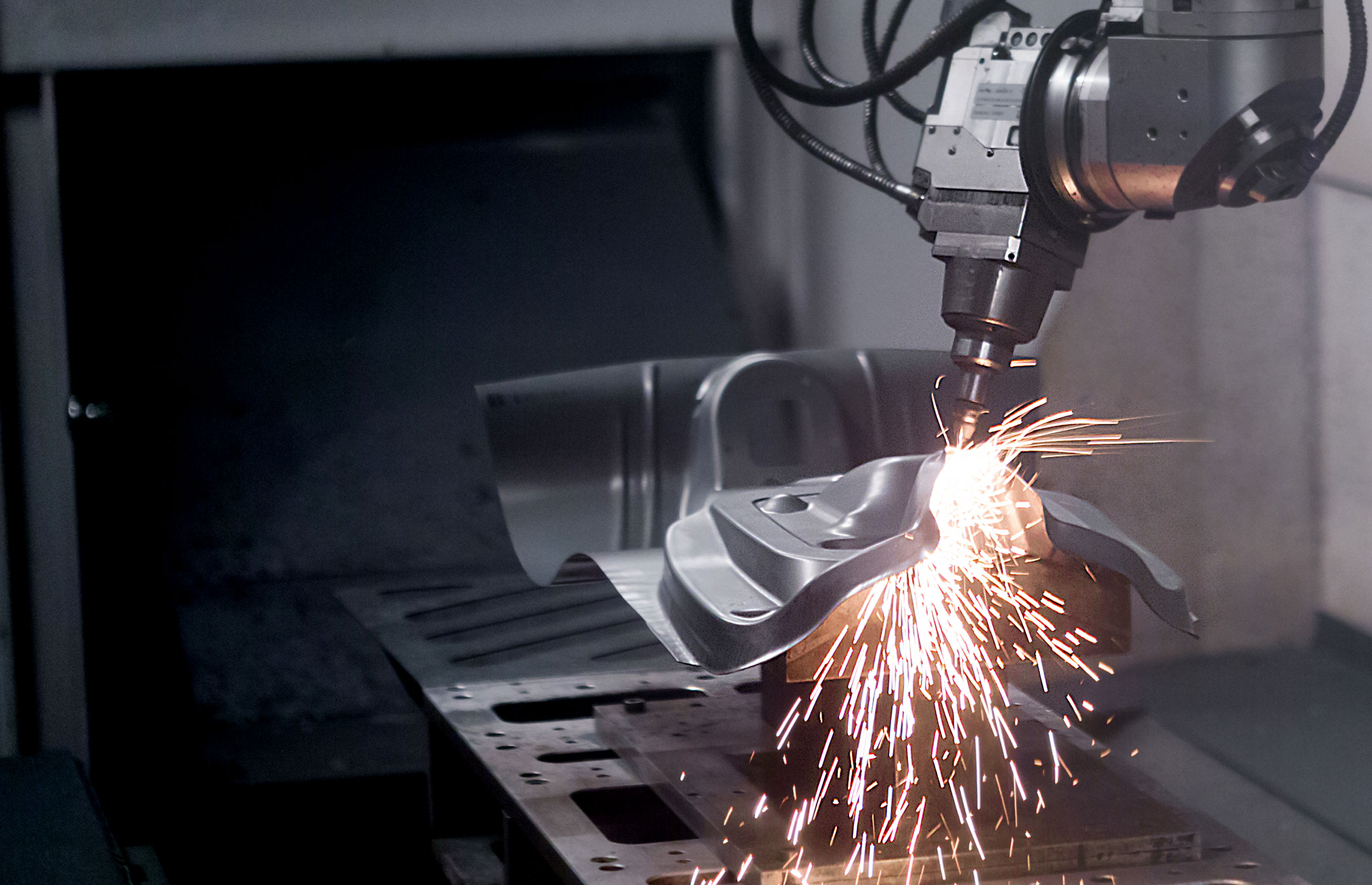

2D and 3D laser cutting

We have a state-of-the-art, evolving robotic laser cutting machine fleet to ensure speed, productivity and flexibility.

Robotized Welding

The robotic welding department is represented by a multiplicity of stations, equipped with the best anthropomorphic robots on the market today.

Machining

We have a department that is constantly in innovation, both technological and professional.

Bending

The department consists of 9-axis controlled electric tube curves, capacity on diameter pipes from 10 to 65 mm.

Assembly Components

It is the latest in the company and allows the finishing and assembly of the components to make the article ready for final use.

Sheet metal products

La Tecnomeccanica Sud can be considered a leader in the molding and deep drawing of cold metals, thanks to the continuous investments in research and technology and with a pressing area capable of meeting most of the needs of the customer and ensuring reliability and quality of the product. The real added value is represented by the close link with the subsidiary CAMS SPA that deals with the design and production of the tools, being able to offer all-inclusive packages and freeing the customer from possible problems related to the use and refinement of the mold during production.

The pressing area is spread over an area of 8,000 square meters and includes presses of different tonnage, of which hydraulics for funnels up to 630 Tons and mechanics with various sizes and assemblies up to 800 Tons.

2D and 3D laser cutting

La Tecnomeccanica Sud has a state-of-the-art and evolving robotic laser cutting machine fleet to ensure: speed, productivity, flexibility, safety, clean cuts and sharp edges.

- 2D/3D LASER CUTTING

- LASERTUBE FROM BARS

- LASERTUBES AFTER BENDS.

Robotized Welding

The robotic welding department of ‘’La Tecnomeccanica Sud’’ is represented by a multiplicity of stations, equipped with the best anthropomorphic robots on the market today is able to carry out welds of different types, from the simplest solutions to the most complex, with MIG/MAG and TIG technology on details both stainless steel and conventional and MIG-BRAZING welding developed by us for special applications.

The robots are installed on upside, column and running route, on the ground or on the portal, and the stations are customized for each type of operation in order to ensure an optimal working condition according to space and processing.

All robotic cell are equipped with an automatic double-faced masking system to make the various activities continuous and faster.

Machining

The mechanical processing department is constantly in innovation, both technological and professional. The machining area is composed of highly automated CNC work centers that perform extremely precise processing on complex details of different types and sizes.

Bending

The department consists of 9-axis controlled electric tube curves, capacity on diameter pipes from 10 to 65 mm.

Assembly Components

The last department born within La Tecnomeccanica Sud is that of finishing and assembling components to make the article ready for final use.

Whether it is an optional or a component for assembly in the company lines, the attentive and prepared staff that operates within this important finishing department, deals with polishing, mounting multiple components and packaging each item.